Standard Seal Range

> Water Pump Seals

> Rubber Bellow Seals

> Diaphragm Seals

> Multi-Spring Seals

> Wave-Spring Seals

> External Seals

> Metal Bellow Seals

> Parallel Spring Seals

> Conical Spring Seals

> Stationaries

Seals by Brand

> Common Brands

> Other Brands

> ALBIN

> AQUAPLUS

> AUSSIE

> BIANCO

> CALPEDA

> CNP

> CORNELL

> CSF INOX

> DAB

> DAVEY

> DONJOY

> EBSRAY

> FLOMAX

> FORRERS

> FYBROC

> GAAM

> GODWIN

> GOULDS

> HAIGH

> HILGE

> HONDA

> INDENG

> JABSCO

> JAVELIN

> JEC

> MASOSINE

> NASH

> ONGA

> PIONEER

> REGENT

> ROBUSCHI

> SAER

> SEEPEX

> SELWOOD

> SHERWOOD

> SIHI

> SPECK

> STALKER

> STANDART

> SYKES

> TSURUMI

> VARISCO

> VIKING

> WANGEN

> WAUKESHA

> ZENIT

Seals by Type

> Pump Type

Seal Refurbishment Services

Elastomer Chemical Compatibility

Seal Face Chemical Compatibility

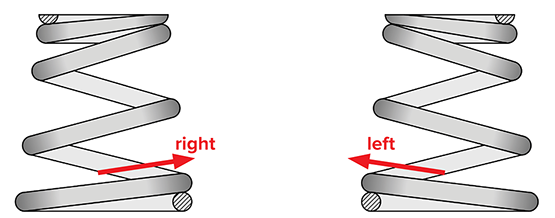

SPRING DIRECTION

When a mechanical seal is spring driven, particularly conical or tapered springs, they become dependent on the direction of rotation.

The easiest way to determine the coil direction is by looking at the spring from side profile:

R/H SPRING

the coils are angling upwards to the right

L/H SPRING

the coils are angling upwards to the left

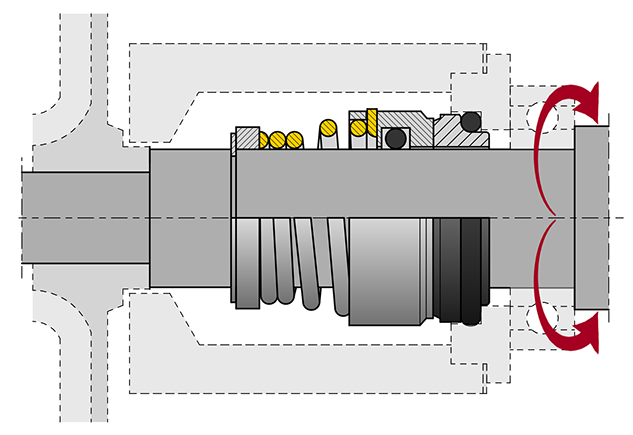

SINGLE SEALS

The most common mechanical seal configuration uses a R/H spring for an internally mounted seal with a clockwise turning shaft.

However, companies may sometimes use an externally mounted seal or an anti-clockwise turning shaft, these options are listed below:

Shafts turning clockwise (viewed from motor-end)

require a R/H SPRING

Motor

End

Impeller

End

Shafts turning anti-clockwise (viewed from motor-end)

require a L/H SPRING

INTERNALLY MOUNTED SEAL

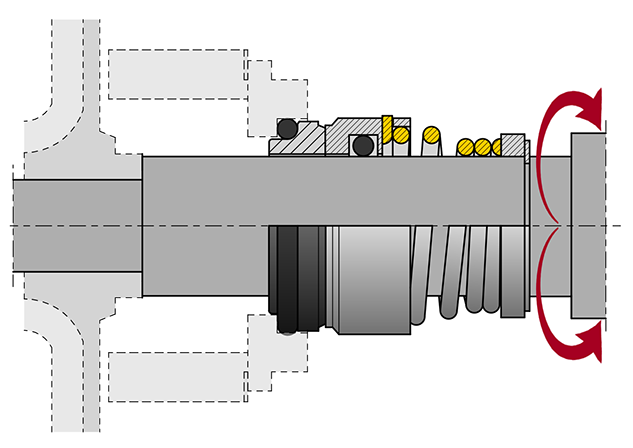

Shafts turning clockwise (viewed from motor-end)

require a L/H SPRING

Motor

End

Impeller

End

Shafts turning anti-clockwise (viewed from motor-end)

require a R/H SPRING

EXTERNALLY MOUNTED SEAL

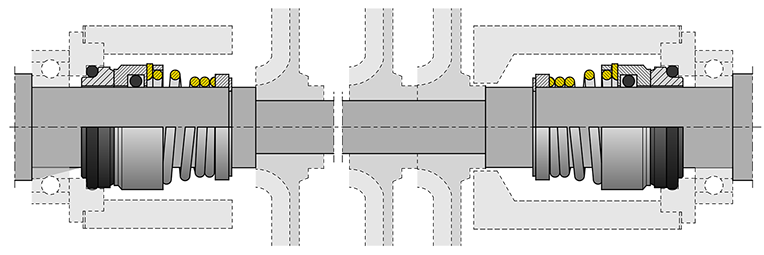

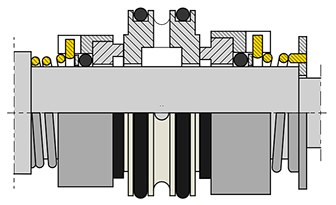

DOUBLE SEALS - BACK-TO-BACK

For spring driven seals in double back-to-back configurations, you will require 1 x R/H spring and 1 x L/H spring, see below two scenarios:

In the example above, two complete mechanical seals are arranged on opposite ends of a pump but facing "back-to-back"

Typically seen in high pressure multi-stage pumps such as those by Ritz (Andritz)

Double "back-to-back" mechanical seals can also be arranged to share the same stationary, such as those by Fristam centrifugal pumps

BACK-TO-BACK MOUNTED DOUBLE SEALS

Whether the shaft is turning clockwise or anti-clockwise, you will require a 1 x R/H SPRING and 1 x L/H SPRING

The spring will follow whichever direction the shaft is rotating when viewed from that end,

i.e. clockwise = R/H spring, anti-clockwise = L/H spring

for double seals mounted in tandem configuration, refer single seal configuration and multiply by 2