Standard Seal Range

> Water Pump Seals

> Rubber Bellow Seals

> Diaphragm Seals

> Multi-Spring Seals

> Wave-Spring Seals

> External Seals

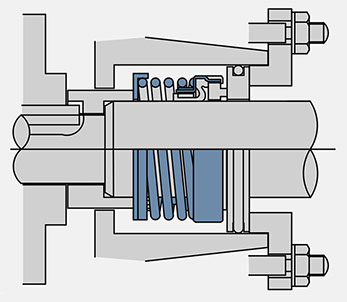

> Metal Bellow Seals

> Parallel Spring Seals

> Conical Spring Seals

> Stationaries

Seals by Brand

> Common Brands

> Other Brands

> ALBIN

> AQUAPLUS

> AUSSIE

> BIANCO

> CALPEDA

> CNP

> CORNELL

> CSF INOX

> DAB

> DAVEY

> DONJOY

> EBSRAY

> FLOMAX

> FORRERS

> FYBROC

> GAAM

> GODWIN

> GOULDS

> HAIGH

> HILGE

> HONDA

> INDENG

> JABSCO

> JAVELIN

> JEC

> MASOSINE

> NASH

> ONGA

> PIONEER

> REGENT

> ROBUSCHI

> SAER

> SEEPEX

> SELWOOD

> SHERWOOD

> SIHI

> SPECK

> STALKER

> STANDART

> SYKES

> TSURUMI

> VARISCO

> VIKING

> WANGEN

> WAUKESHA

> ZENIT

Seals by Type

> Pump Type

Seal Refurbishment Services

Elastomer Chemical Compatibility

Seal Face Chemical Compatibility

SEAL METALLIC MATERIALS

Metallic parts make up the remaining components in a seal, some critical to operation such as the springs and even as bellows.

The selection of metallic components is generally straightforward. and are selected based on corrosion resistance with the pumped media.

COMPARISON OF INDIVIDUAL PROPERTIES

Metel:

UNS Designation:

Composition:

Other Names:

Usage:

Tensile Strength:

Extension Strength:

Hardness:

316

Stainless Steel

S316000

~66% Iron

16 - 18% Chromium

10 - 14% Nickel

2 - 3% Molybdenum

2% Manganese

0.08% Carbon

316 S.S.

all areas

520 MPa

205 MPa

170 HB

304

Stainless Steel

S30400

~70% Iron

18 - 20%% Chromium

8 - 10.5% Nickel

2% Manganese

0.07% Carbon

304 S.S.

all areas

520 MPa

205 MPa

201 HB

C-276

Hastealloy® C

N10276

~57% Nickel

15 - 17% Molybdenum

14.5 - 16.5% Chromium

4 - 7 % Iron

3 - 4.5% Tungsten

0.01% Carbon

Hastealloy C-276

agressive chemical

600 MPa

205 MPa

87 RB

AM350

Alloy 350

S35000

~75% Iron

16 - 17% Chromium

4 - 5% Nickel

2.5 - 3% Molybdenum

0.5% Silicon

0.07% Carbon

AM 350

metal bellows

1,105 MPa

415 MPa

95 RB

C-42

Carpenter 42

K94101

~54% Iron

42 - 44% Nickel

1% Chromium

1% Manganese

0.5% Silicon

0.1% Carbon

Carpenter 42

low expansion

-

-

-

631

Stainless Steel

S17700

~70.5 - 76.8% Iron

6.5 - 7.8% Nickel

16 - 18% Chromium

0.75 - 1.5% Alu.

1% Manganese

0.09% Carbon

SUS631 / 17-7 PH

wave springs

1,230 MPa

1,030 MPa

388 HB

ratings should be interpreted as: ★★★★ = excellent ★★★ = good ★★ = fair ★ = poor

Hydrocarbons:

Acids:

Bases:

Chlorides:

Chemical Resist:

★★★★

★★★

-

★★

★★★

★★★★

★★

-

★

★★

★★★★

★★★

★★★

★★★

★★★

★★★

-

-

-

★★

★★★

★

★

★

★

★★★★

★★★

-

★★

★★★

DETAILED INFORMATION

316 S.S

316 Stainless steel are considered the Austenitic workhorse of the mechanical seal industry, used as the base material for most seal designs. Other variations of this alloy such as 316L and 316Ti are used depending upon secondary operations (such as welding) or geographic availability, respectively. Like all stainless steels, 316 derives its corrosion resistance from the presence of chromium and the formation of a passive oxide layer. It is easily welded and is used for many welded metal bellows applications.

For mechanical seals, 316 stainless steel is used for a wide variety of applications from drinking water to hot sour crude oil. It is resistant to many acids and caustics although these should be checked for the concentration and temperature for each specific application. It is compatible with most other organics and hydrocarbons. 316 should bot be used in services with high chlorides since it is susceptible to pitting corrosion.

304 S.S

304 Stainless steel is another popular high-performing alloy similar in general mechanical properties to 316. The decreased nickel content and exclusion of molybdenum gives 304 lesser chemical resistance but compositionally has higher hardness, tensile strength and melting points. 304 is also the most universally used stainless steel across all industries, making it less expensive overall. For applications with powerful corrosives or chlorides, it is recommended to use 316 grade, however for application using milder acids or where salt exposure isn't a concern, 304 grade can work just as well.

C-276

Alloy C-276 is a widely used "superalloy" in highly aggressive environments. The combination of high molybdenum and chromium content, along with the addition of tungsten make Alloy C276 highly resistant to chloride stress corrosion cracking, pitting and corrosion and is suitable for seawater, brine, acids, strong oxidisers and hydrocarbons.

Hastealloy® is the common brand-name for nickel-molybdenum "superalloys", and is the main body material for our H670 metal bellows seals.

AM350

Alloy 350 is a chromium-nickel-molybdenum alloy that exhibits high strength in high temperature applications. It is often used in aircraft and turbine applications. This allow is easily welded so it found use as a material for welded metal bellows. For many years, this alloy was the standard material for bellows in high temperature applications. Since most of the high temperature applications were found in hydrocarbon processing application, these alloys became exposed to more aggressive environments as more sour crudes were being processed. This resulted in many seal failures and this alloy was eventually replaced with alloy 718 in refinery services.

Alloy 350 is still used in some welded metal bellows seals although it is limited to less aggressive environments. Since this allow was never considered a highly corrosion resistant material, it is difficult to obtain chemical compatibility data or corrosion rates for most services.

C-42

This nickel-iron alloy was developed by Carpenter Technology® to be a 'Low Expansion' alloy that has a virtually constant low rate of thermal expansion at high temperatures. For high temperature services, seal designs use a low expansion alloy shrink-fits on seal faces. For mechanical seals, this alloy is used primarily as a seal face holder for high temperature metal bellows seals, which are used in hot refinery services. As the seal faces are shrink-fitted into the holder, the properties of Carpenter 42s low expansion ensure the faces are sealed tight.

316 S.S

613 Stainless Steel (also known as UNS S17700 or 17-7 PH) has anti-corrosion capabilities like 304, however it is almost exclusively used in wave-spring manufacturing due to its significantly higher tensile and extension strength and its ability to withstand high fatigue load and stress.

OTHER METALS

Other metals used in the industry. although must less common

A-20

Alloy 20 is a nickel-chromium-molybdenum alloy that was originally developed for applications in hot sulfuric acid. Today it is still used in this service as well as other aggressive chemical applications. It is considered as resistant to applications that cause stress corrosion cracking. It is used in applications in the manufacture of rubber high-octane gasolines and pharmaceuticals.

Alloy 20 can be readily welded without carbide precipitation so it has been used in welded metal bellow seal designs. Other adapter hardware such as sleeves and glands will generally be made from this allow also to match the chemical resistance of the bellows. Alloy 20 is normally used only when no other common alloys are acceptable for a specific application.

A-400

Alloy 400, or Monel, is a copper-nickel-alloy that exhibits good corrosion resistance against many chemicals. These include seawater, sulfuric acid, hydrochloric acid and alkalis. This material is generally not susceptible to stress corrosion cracking. For mechanical seals, alloy 400's most common use is in hydrofluoric acid applications. In this service it is used for both basic metal parts as well as welded metal bellows. For components that require higher strength (such as set screws and fasteners), a related material, alloy K-500 is often used.

A-718

Alloy 718, or Inconel, is a nickel-chromium alloy that exhibits both excellent corrosion resistance and high temperature properties. This alloy can be heat-treated to obtain the required physical properties for a specific application and these properties do not significantly degrade over the temperature range typically seen in mechanical seals. For this reason, alloy 718 has become the standard alloy for welded metal bellows in high temperature hydrocarbon processing applications. These alloys, with proper heat-treating, resist attack by sour crudes (sulfur) and other chemical found in these services.

For mechanical seals, alloy 718 is used primarily for welded metal bellows. In a limited number of seal designs, components attached to alloy 718 are also manufactured out of alloy 718 for the purpose of matching thermal expansion between components.

BRASS

BRONZE

Some older mechanical seals used to be made of brass or bronze, however they have seen less use as mechanical seal development has improved and stainless outclasses in almost all mechanical properties.

NI-RESIST

Ni-Resist alloy grade are cast iron grades that provide good hardness, dampening and some corrosion resistance. However these grade are very brittle and cannot be welded. While some older mechanical seals had Ni-resist housings, these were phased-out for much better grades of stainless steel.

Information courtesy of Huebner, Michael (2005). Material Selection For Mechanical Seals. Texas A&M University. Turbomachinery Laboratories.