Standard Seal Range

> Water Pump Seals

> Rubber Bellow Seals

> Diaphragm Seals

> Multi-Spring Seals

> Wave-Spring Seals

> External Seals

> Metal Bellow Seals

> Parallel Spring Seals

> Conical Spring Seals

> Stationaries

Seals by Brand

> Common Brands

> Other Brands

> ALBIN

> AQUAPLUS

> AUSSIE

> BIANCO

> CALPEDA

> CNP

> CORNELL

> CSF INOX

> DAB

> DAVEY

> DONJOY

> EBSRAY

> FLOMAX

> FORRERS

> FYBROC

> GAAM

> GODWIN

> GOULDS

> HAIGH

> HILGE

> HONDA

> INDENG

> JABSCO

> JAVELIN

> JEC

> MASOSINE

> NASH

> ONGA

> PIONEER

> REGENT

> ROBUSCHI

> SAER

> SEEPEX

> SELWOOD

> SHERWOOD

> SIHI

> SPECK

> STALKER

> STANDART

> SYKES

> TSURUMI

> VARISCO

> VIKING

> WANGEN

> WAUKESHA

> ZENIT

Seals by Type

> Pump Type

Seal Refurbishment Services

Elastomer Chemical Compatibility

Seal Face Chemical Compatibility

SEAL IDENTIFICATION

The process below demonstrates the correct procedure of measuring and properly identifying a mechanical seal in 3 easy steps:

STEP 1: IDENTIFYING SEAL TYPE & ARRANGEMENT

A mechanical seal can be identified, often visually, by looking our for how it's mounted to the shaft:

RUBBER BELLOWS MOUNTED

- Diaphragm Seals

O-RING MOUNTED

- Parallel Spring

- Conical Spring

- Multi Spring

- Wave Spring

- Metal Bellows

- PTFE Bellows

A mechanical seal can also be identified by arrangement:

DOUBLE SEAL

- Back-to-back

- Face-to-Face

- Tandem

SINGLE SEAL

- Internally Mounted

- Externally Mounted

STEP 2: IDENTIFYING SEAL SIZE & MATERIAL

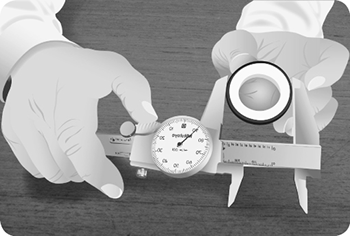

In determining the size of your mechanical seal, use a precision measuring tool, ideally a set of vernier calipers to measure the following:

MEASURING & DETERMINING SHAFT SIZE

The shaft size, often denoted as 'D1', can be measured either:

1. Directly on the shaft where the seal is mounted or;

2. The inside diameter (ID) of your mechanical seal where for:

a) Rubber bellow mounted seals is the ID of rubber bellow

b) O-ring mounted seals is the ID of the O-ring

IDENTIFY THE SEAL FACE MATERIALS

Common seal face materials can be identified visually:

Carbon (CAB):

Ceramic (CER):

Silicon Carbide (SiC):

Stainless Steel (S.S):

Tungsten Carbide (TC):

Black in colour, rough to touch

White in colour, smooth to touch

Blue-grey in colour, smooth to touch

Metallic, smooth to touch

Similar to S.S, heavier, smooth to touch

MEASURING STATIONARY TYPE, CAVITY & HEIGHT

Determine the style of your stationary, the two most common being

cup mounted or o-ring mounted.

To measure cup mounted stationaries:

1. Measure the outside diamater (O.D.) of the rubber cup (D7)

2. Measure the height (L4) from the rubber cup to the seal face

To measure o-ring mounted stationaries:

1. Measure the OD of the o-ring

2. Measure the height where for:

a) o-rings located in the middle, from the back face to front face

b) o-rings located in the back, from the back face to the o-ring

STEP 3: IDENTIFYING SEAL BY PUMP DESIGNATION

Often your pump type, manufacturer or model number can be used to determine whether the mechanical seal is standard or pump-specific:

DETERMINE THE PUMP TYPE & MANUFACTURER

Determine what type of pump, i.e. centrifugal, submersible, lobe, gear, agitator or compressor

Determine what pump brand, i.e. Grundfos, Ajax, Alfa Laval, APV, Ebara, Flygt, Inoxpa & Southern Cross etc.

IDENTIFYING THE PUMP MODEL & SIZE

Each pump manufacturer has their own designation or type key for their respective pump ranges.

We can normally determine the seal if you send a photo of the pump's nameplate