Standard Seal Range

Seals by Brand

Seals by Type

Seal Refurbishment Services

Elastomer Chemical Compatibility

Seal Face Chemical Compatibility

BARRIER / BUFFER FLUIDS

With the growing popularity of double seal arrangements, including back-to-back, tandem or face-to-face, these arrangements necessitate an inner chamber between the seals for a liquid / gas buffer or barrier fluid to operate.

Below are some best practices for liquid buffer and barrier fluids. By selecting an appropriate fluid and following proper maintenance procedures, end users can promote system reliability and extend their systems' operating lives.

BARRIER VS BUFFER FLUIDS

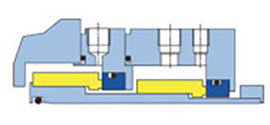

Tandem arrangement

unpressurised, uses buffer fluid

Back-to-back arrangement

pressurised, uses barrier fluid

In addition to process fluid, all double seals use an external fluid. Depending on the arrangement, this external fluid is called barrier fluid or buffer fluid. Pressurised seal arrangements, including back-to-back and face-to-face use barrier fluid, which isolates the pump process liquid from the rest of the system. Tandem seal arrangements, which are unpressurised, use buffer fluid.

FLUID SELECTION

There is a wide range of barrier / buffer fluids pump users can select from, each with their own pros and cons:

GLYCOL SOLUTIONS

Glycol Solutions usually contain 50% ethylene glycol and 50% water, and are the simplest and most common barrier or buffer fluid used in the pumping industry. Users should only used uninhibited solutions, as inhibited solutions such as antifreeze damage the seal faces. Since ethylene glycol is a toxic compound which sees restricted use in some area, end-user may need to use propylene glycol instead.

ALCOHOL

As alcohols have a high rate of evaporation, frequent refills may be required and is generally best-suited for low-temperature services.

Although methanol has been used in the past as a buffer fluid for tandems seals, it is toxic and has a low boiling point and low viscosity.

Propanol has replaced methanol as a a buffer fluid however propanol has an exposure limit of 200 ppm

KEROSENE OR DIESEL FUEL

The viscosity of diesel fuels and deodorised kerosenes can provide adequate seal face lubrication through a wide temperature range. However they are classified and volatile organic compounds (VOC) and is flammable at high temperatures.

PETROLEUM BASED HYDRAULIC AND LUBRICATING OILS

Because these are are widely available, they are popular choices. However, the viscosity of these oils can cause carbon seal face blistering, particularly with oils that are Grade 32 or high on the ISO scale.

Experience has shown that synthetic oils perform between than conventional turbine oils; this may be partially due to the (generally) lower viscosity of the synthetics. Automatic transmission fluid is similarly a poor barrier fluid, with the assumption that various additives are the problem.

SYNTHETIC BASED HYDRAULIC AND LUBRICATING OILS

These have grown increasingly popular in the past decade and is usually polyalphaolefin-based ranging from ISO Grade 5 to Grade 20. Lower-viscosity synthetics are the most popular option among end-users. Higher-viscosity synthetics, which are more expensive, are the best choice for applications with high temperatures or low shaft speeds.

HEAT TRANSFER FLUIDS

Heat transfer fluids that have the ability to provide adequate lubrication throughout a wide range of temperatures and pressures can be used as buffer or barrier fluids. Heat transfer fluids encompass a broad spectrum of chemical families (water, steam, inorganic salts, liquefied metals and organic class fluids.

Organic class heat transfer fluids, include petroleum-based fluids (also called 'hot oils) and synthetic aromatic fluids. Synthetic aromatic fluids, (such as Dowthern fluids) offer higher thermal stability, broader temperature ranges and much more effective than petroleum 'hot oils'. Dowtherm is a family of synthetic heat transfer fluids that includes Therminol, Multitherm and Paratherm etc.

TEMPERATURE GUIDELINES FOR FLUID CLASSES

There is a wide range of barrier / buffer fluids pump users can select from, each with their own pros and cons:

GLYCOLS:

Min: -29°C

Max: 85°C

ALCOHOLS:

Min: -124°C

Max: 70°C

KEROSENE / DIESEL:

Min: -18°C

Max: 82°C

PETROLEUM BASED OILS:

Min: -29°C

Max: 150°C

SYNTHETIC BASED OILS:

Min: -32°C

Max: 250°C

HEAT TRANSFER FLUIDS:

Min: -32°C

Max: 250°C